| |

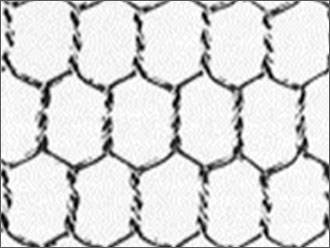

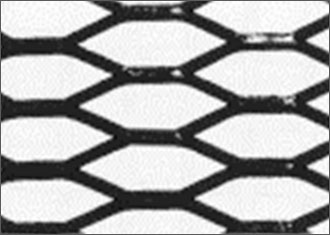

Wire mesh can be made of different alloy of metal, as well as plastics and synthetic like materials like Polypropylene, polyethylene, polyester, nylon and woven or welded to form a variety of shapes, opening sizes and material thickness. |

| |

|

|

|

|

|

|

Knitted Wire Mesh is created from round or flattened wires and is not limited to steel alloys. Different material types, such as metal as well as plastics and synthetic materials, like Polypropylene, Polyethylene, Nylon and Teflon can be created from different diameter wires, densities, structures and forming pressures to suit specific needs of the end-users.

Knitted mesh can be used in the automotive, electronics, aerospace, telecommunications, medical, military installations, marine and in technical enclosures for vibration control, sound reduction and attenuation, EMI shielding and liquid and gas filtration.

Crimped Knitted Mesh is used to weave compressed units for Frame Arrestors. Knitted Mesh is available in mesh rolls, circular or rectangular as Demister Pads, complete with filters and as compressed elements. |

| |

|

|

|

|

|

|

|

|

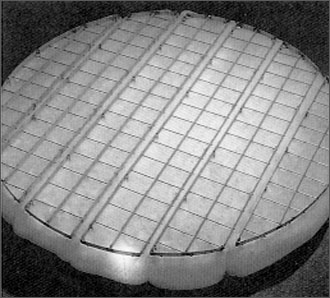

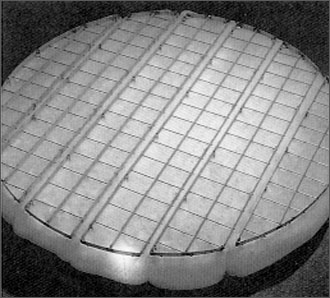

Demister Pads, also known as Mist Eliminator, Diesel injector, Filter, Flame Arrestors, Knitted Mesh, Mist Screen and Socks, are manufactured according to customer’s specifications.

A demister or mist eliminator is an entrainment separator used for efficient entrainment of liquids or mist removal in any Liquid - Gas / Vapour processing operation. It is a tailor-made product specially designed and manufactured out of knitted wires. When properly applied, it can achieve 99.97% separation of entrapped liquid in a vapour stream.

Demisters are utilised in petroleum refining, petrochemical industry, gas chemistry, synthetic chemistry, salt and sugar manufacturing and other chemical industries. They are also employed in packed towers, dust arrestors and air filters in various enterprises, or for chemical-reaction acceleration by painting the filament surfaces with catalyst (in both separation and reaction). Other applications include the special gasket in cabinets of electronics instruments and vibration and sound insulation. |

| |

|

|

|

|